|

Home

| pfodApps/pfodDevices

| WebStringTemplates

| Java/J2EE

| Unix

| Torches

| Superannuation

|

| About

Us

|

|

Garage Heater using a Truck Diesel Heater

|

by Matthew Ford 19th October 2022

(original 16th October 2022)

© Forward Computing

and Control Pty. Ltd. NSW Australia

All rights reserved.

This project was completed by George using a

Diesel powered truck heater. George chose pfodApp

to control the heater because

“Initially I thought

interfacing the phone to the processor would be the most challenging

aspect, but pfodApp

handled all the nitty-gritty of that aspect easily and flawlessly.

Using the pfodDesigner

generated code produced it simply worked!”

The aim of this Project was to be able to remotely control a small diesel fuelled air heater in the garage via a mobile phone. There are 5 buttons on the heater display (& control) module used for the various heater functions, so the aim was to have the system mimic hand presses on those buttons and monitor various aspects from the heater at the same time. Having the processor literally press buttons on the control unit has the added advantage that it electrically de-couples the two systems completely.

For a list of the main parts see Components.pdf Here is the manual for the truck heater.

The free pfodDesigner app was used to build the menu for the phone, and the code it produced was fed into the Arduino IDE, tinkered about with a bit, then uploaded into the control processor (an ESP8266 WeMos D1 Mini in this case).

Once up and running, commands were sent from the phone via the pfodApp to the processor which in turn activated relays to push the required buttons (for the required press length) on the heater control panel while also sending back assorted monitoring signals. Initially I thought interfacing the phone to the processor would be the most challenging aspect, but pfodApp handled all the nitty-gritty of that aspect easily and flawlessly. Using the pfodDesigner generated code produced it simply worked! To be honest, I don’t understand a lot of it, but it turned out to be straightforward to tweak it a bit to personalise the output – even with my very limited C++ coding ability. Lots of kudus to it.

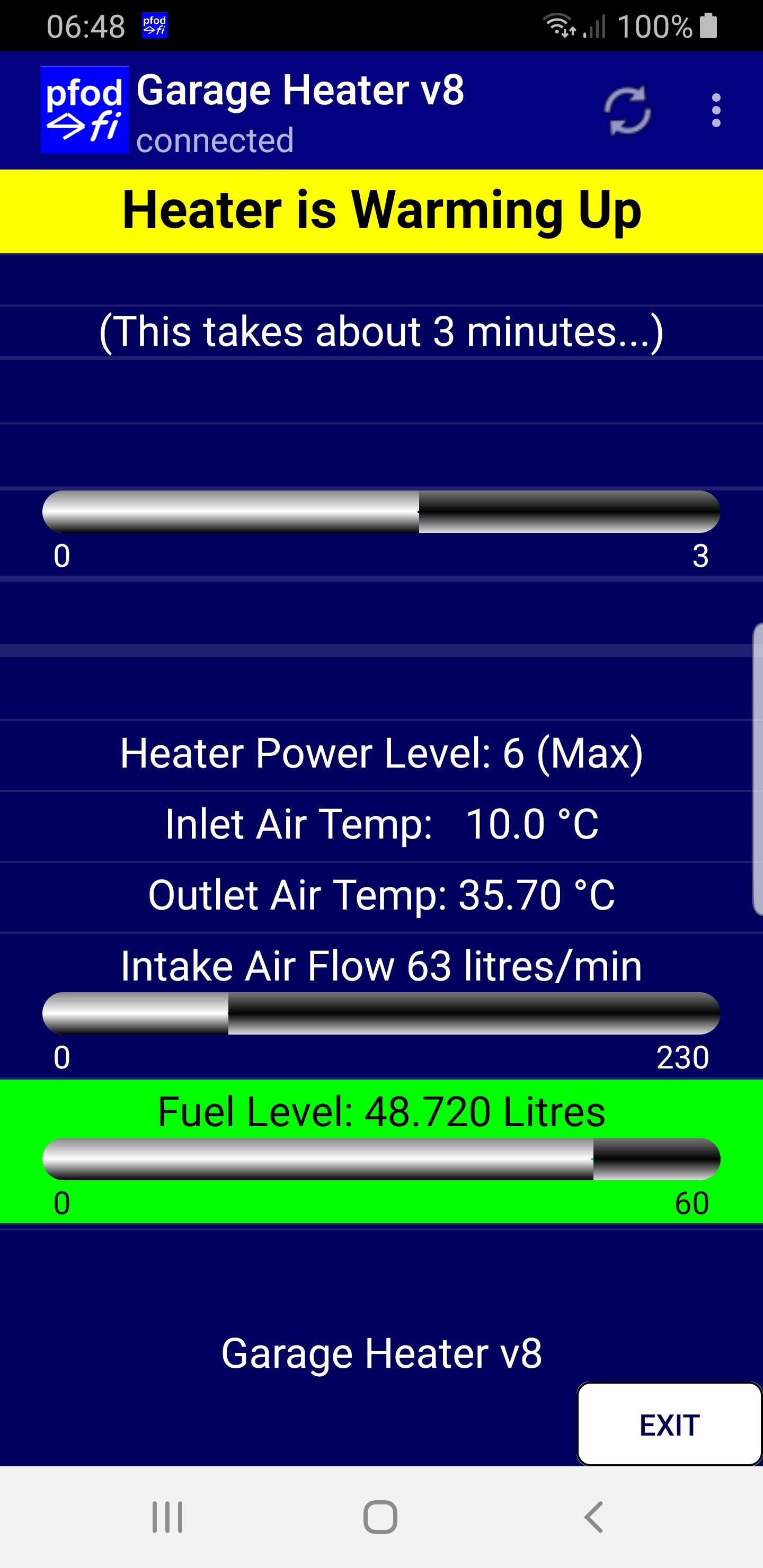

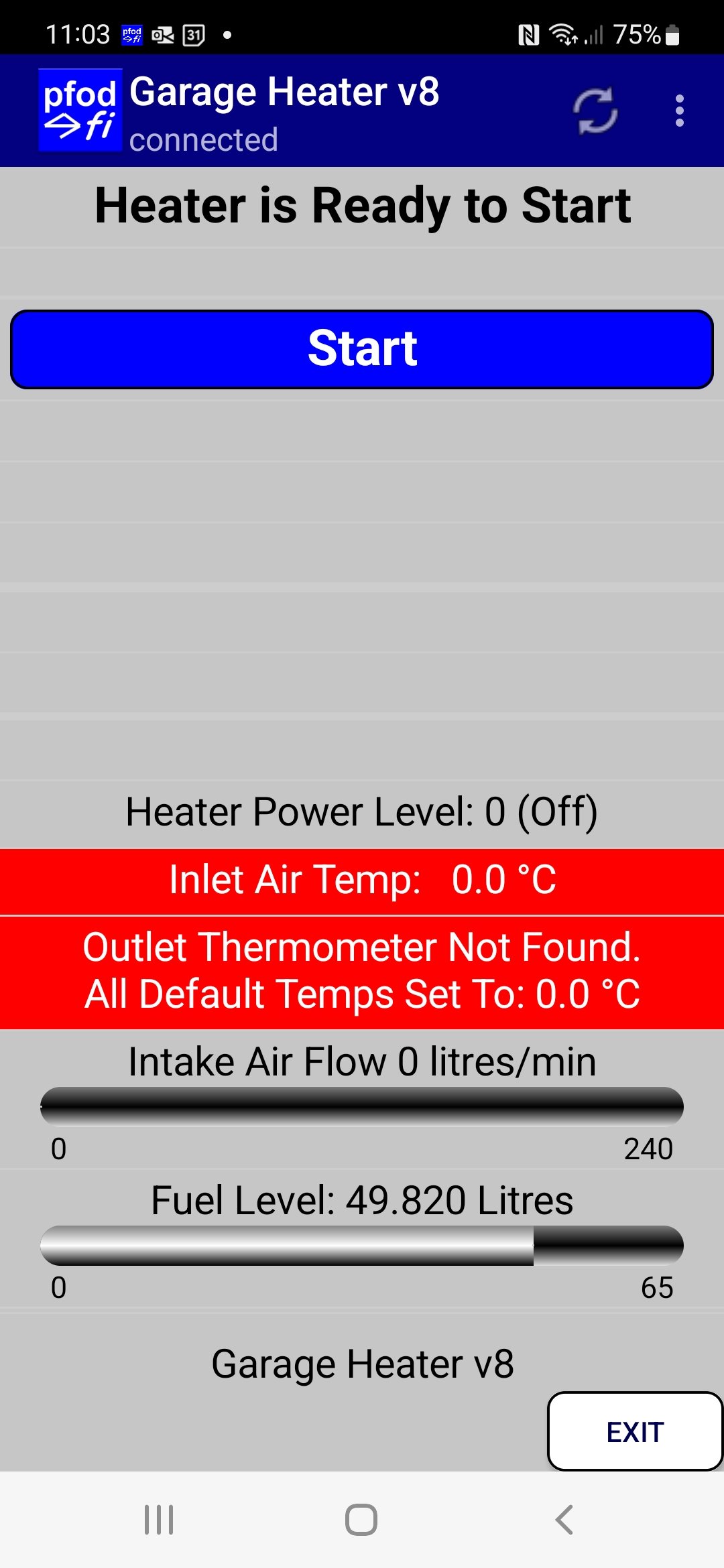

The final sketch is Garage_Heater_v8.ino The menus items were designed using the free app pfodDesigner and the code generated for a WiFi connection. As the heater changes state the menu items are updated/hidden/shown as appropriate.

The heater itself goes through assorted start-up and shut-down phases (as well as different responses to long or short button pushes) so the code takes this account.

No direct feedback was available from the heater module, so assorted sensors were added to capture the required data. Real-time intake air flow, temp readings, and weigh scales values are all fed back to the phone and displayed on the menu.

(click images for full size versions)

During testing it was discovered that, if the processor was left powered up and the heater off, it would start itself for no apparent reason (maybe once a fortnight), so a remote Sonoff switch was included to switch off all power to stop this happening. Another glitch was that (very) occasionally, the processor would lock up and apply a constant drive to the solenoids, so to mitigate for this, 555 Relay timers were included to cut the solenoid supply after a few seconds irrespective of the processor relay signals.

The current code does not include any emergency shut-down routines, but the heater does (internally) monitor itself anyway, and will shut itself down it anything goes wrong. It’s debatable whether extra coded routines are actually required, but maybe will be on the next revision. As a back-up, a WiFi CCTV PTZ was added to monitor the heater, display panel & fuel tank etc., and has the added bonus that it can also be used to monitor the rest of the garage remotely.

However irreparable damage and/or even fire would occur if the heater lost AC power while running and wasn’t able to complete the cooling down cycle (it depends on fan air flow to stop it overheating). To mitigate for this scenario, system power is supplied via a UPS.

As it stands, the power level can’t actually be remotely decremented once it’s at full power – most of the hardware is in place, but would require another relay to implement – it’s on my ‘to-do’ list, but once the heater is at full power, I never reduce it before it’s switched off anyway, so it’s not really a ‘must-have’ facility.

The heater itself is housed in a sealed & insulated box both for soundproofing and to allow both combustion air and warm output air flow to be measured and be per-filtered through a large foam filter (it can get very dusty in the garage!). Intake air flow and temp is monitored at the main inlet, then both flows are further filtered at the heater.

The burner exhaust is routed to the outside, and the warm air is ducted to the bench for that warm cosy glow.

(click image for full size version)

(click image for full size version)

Fuel comes from a 60l barrel sitting on top of 4-wire wheatstone bridge configured strain gauge scales (calibrated to convert kg to litres of red diesel). The scales in turn are sitting on a skate. The fuel line can be disconnected (via a quick connect) and the tank can be rolled out from under the bench for easy access to refill it.

AndroidTM is a trademark of Google Inc. For use of the Arduino name see http://arduino.cc/en/Main/FAQ

The General Purpose Android/Arduino Control App.

pfodDevice™ and pfodApp™ are trade marks of Forward Computing and Control Pty. Ltd.

Contact Forward Computing and Control by

©Copyright 1996-2020 Forward Computing and Control Pty. Ltd.

ACN 003 669 994